Which came first, the chicken or the egg? The same question goes for noise & vibration and the smart money is on the latter, but they often go hand-in-hand and that’s particularly true (pun alert) for hand-guided or operated tools. The author recently bought a battery-powered strimmer and was not surprised that it was noisy but rather taken aback that their fingers were tingling after just a few minutes use. A quick glance at the handbook showed some laboratory-based measurements for both noise and vibration (for CE/UKCA safety marking purposes) but the uncertainty in the vibration measurement was the same as the vibration level itself but then there was a statement that levels in use may be even higher!

What is HAVS, why is it important?

How is the average consumer meant to interpret that or indeed a professional doing a risk assessment for exposure in the workplace where use of tools may be for several hours a day? Let’s investigate.

Effects of vibration exposure

According to the seminal text [1] by Professor John Cherrie et al, exposure to vibration is widespread in industry and is of concern because it may cause discomfort plus vascular, neurological or musculoskeletal disorders. The use of handheld power tools exposes workers to hand-arm vibration, which may cause the tips of the fingers to become blanched, known as vibration white finger (VWF) with loss of feeling and dexterity. The tingling experienced is a pre-cursor to this.

Excessive exposure over long periods can result in hand arm vibration syndrome (HAVS) or carpal tunnel syndrome (CTS) and rather like noise induced hearing loss (NIHL), it is often diagnosed when it is too late to do anything, the permanent damage having already been done. HAVS can be extremely debilitating that affects a person’s ability to continue to work and carry out the most routine of tasks such as fastening a button.

The level of vibration from a tool is just one of the risk factors. The other main workplace factors that affect risk are (low) temperature, grip strength (ergonomics), tool productivity and individual susceptibility (e.g., blood flow into the hands) and smoking.

Sectors affected

About 30 million people are exposed to hand-arm vibration at work in Europe (2m in the UK alone) from using angle grinders, impact wrenches, air chisels, strimmers, chainsaws and hedge cutters to name but a few tools, and it is estimated that there are perhaps 30-40% who are at risk of developing the disease. The sectors at most risk are: -

· Building and maintenance of roads and railways

· Construction

· Estate management & maintenance

· Forestry

· Foundries

· Heavy engineering

· Manufacturing concrete products

· Mines & quarries

· Motor vehicle manufacture & repair

The situation in the USA according to the US Navy [2] is that about 2.5 million workers are exposed daily to HAVS from the power tools they use and that documented workplace prevalence of HAVS ranges from 20-50%. The latter is consistent with the estimates in Europe, but the absolute number seems an underestimate based purely on a pro-rata working population and possibly reflects the lack of a legislative focus?

Vibration legislation

Nearly twenty years ago the EU published the Physical Agents Directive 2003/10/EC, on noise & vibration, aimed at limiting exposure, which for vibration was implemented in the UK as the Control of Vibration at Work Regulations (2005). It set out requirements primarily regarding the assessment of the risk to health to employees from vibration, investigating whether they are likely to be exposed above the daily exposure action value (EAV), measures to control exposure, health surveillance and training.

Where there’s blame, there’s a claim

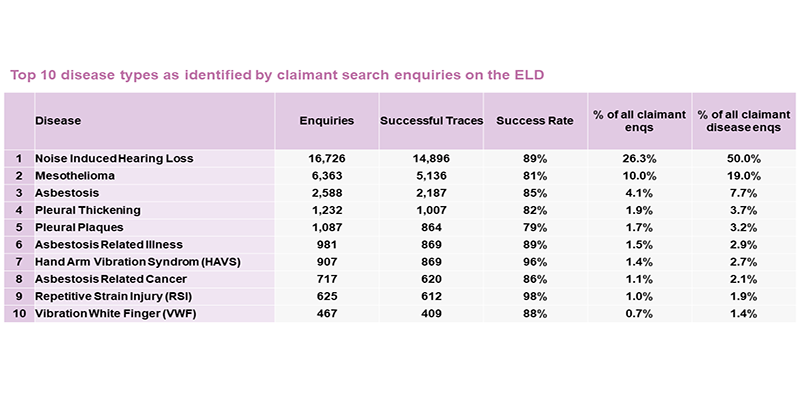

The 2000 annual report by The Employers’ Liability Tracing Office (ELTO) showed the rank of claimant searches for industrial exposure-based diseases (see Table 1)

Table 1

ELTO was founded by the insurance industry in 2011 to give claimants easy access to their employer’s liability insurance data and their 2022 report is expected imminently. ELTO holds more than twenty-five million insurance policies spanning more than a hundred years, important because of the lag between exposure and diagnosis.

Balfour Beatty hit with £500,000 HAVS fine - Construction Manager - 18/08/18

Places for People Homes Fined £600K after employees develop HAVS - PBC Today - 14/11/19

Interestingly, HAVS and VWF are in 7th and 10th position respectively and a typical claim according to Essel Acoustics [3] is in the range £10-15k but the issue has been widely covered in the health & safety press who have regularly reported six figure fines (following the introduction of the Sentencing Guidelines in 2016) as well as unquantifiable reputational damage for the employer.

The HSE had earlier conducted an investigation [4] and estimated the uninsured costs to be a significant multiple of the insured costs by a factor of 8 to as much as 36 times! So, for the typical HAVS claim mentioned above, the uninsured cost is likely to range from £80k to £540k.

Control Measures

Unlike hearing protection for noise exposure there is no real effective PPE for vibration despite the claims that anti-vibration gloves may make but whatever their merits, they must conform to EN ISO 10819 [5]. The standard is designed to measure the vibration transmissibility from a vibrating handle – through a glove – to the palm. Wrapping some rubber or other elastic material around the handles of a vibrating tool as a control measure will have little impact on the vibration and may in fact makes things worse! The best form of control is therefore: -

· Investigating alternative ways of carrying out the task not involving vibration

· Ensuring that there are purchasing policies and procedures to select and purchase low vibration equipment

· Using low-vibrating equipment or operate it remotely

· Minimising individual exposure by rotating workers using vibrating equipment

· Ensuring that equipment is regularly and properly maintained

· Providing regular health checks to those employees at risk

· Instructing employees on the health risks of vibration, the signs of vibration injury and how to report early signs of ill health, the precautionary and preventative measures available and the procedures for reporting equipment defects

It is important to note that many UK prosecutions for HAVS have centred around the lack of health surveillance.

In future articles, we will look at the maths behind the EAV in more detail, how to make a measurement and what are the features that make a good measuring instrument.

References

1. Monitoring for Health Hazards at Work, Cherrie J, Semple S, Coggins M. 5th Edition, 2021. Wiley Blackwell

2. https://www.gsa.gov/cdnstatic/Hand-Arm_Vibration_Syndrome_01-06-2016.pdf

3. https://esselacoustics.com/news/no-win-no-fee-litigation-2/

4. HSG245 – Investigating accidents and incidents, HSE Books

5. EN ISO 10819 Mechanical vibration and shock – Hand-arm vibration – Measurement and evaluation of the vibration transmissibility of gloves at the palm of the hand